One-Bath, One-Step Dyeing for Polyester-Cotton Fabrics — A New Engine for Green Transformation in the Textile Industry

2025-08-29 10:18

Independently developed and promoted by Shandong Ever Biotechnology Co., Ltd., the polyester-cotton one-bath dyeing process combines the traditional separate dyeing procedures for polyester and cotton into a single bath, one-step method. This innovation shortens processing time by 50%, significantly enhances production efficiency, reduces labor requirements, and doubles output without increasing manpower or equipment. It greatly lowers overall enterprise costs, strengthens market competitiveness, and creates greater profitability for customers.

Honors and Recognition

• Included in Shandong Province’s Enterprise Innovation Achievements Project Database and recognized as an outstanding technological innovation achievement.

• Awarded First Prize in the 6th Shandong Industrial Engineering Application Case Competition (“Rhein-Coster Cup”).

• All auxiliaries and dyes used in this process have passed ZDHC MRSL V3.1 Level 3 certification.

Advantages of the Polyester-Cotton One-Bath Dyeing Process

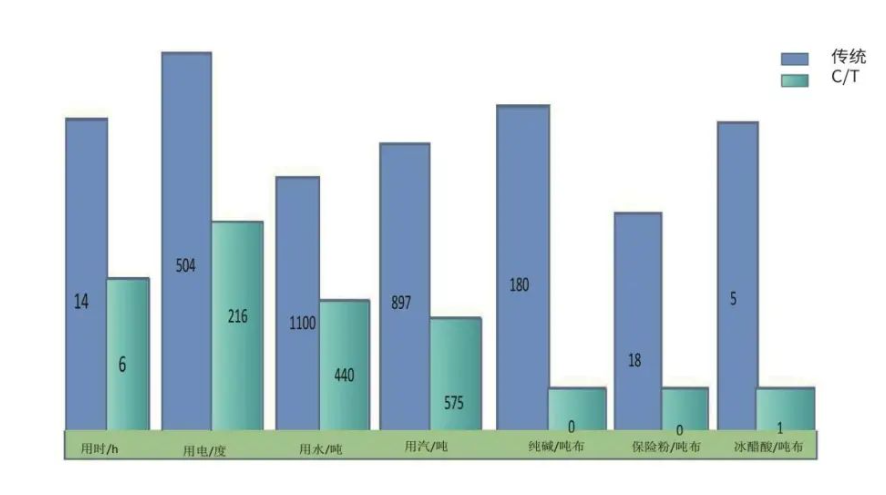

1. Efficiency & Capacity: Simplified process, easy operation, and complete dyeing cycle within 6–7 hours, resulting in remarkable productivity gains.

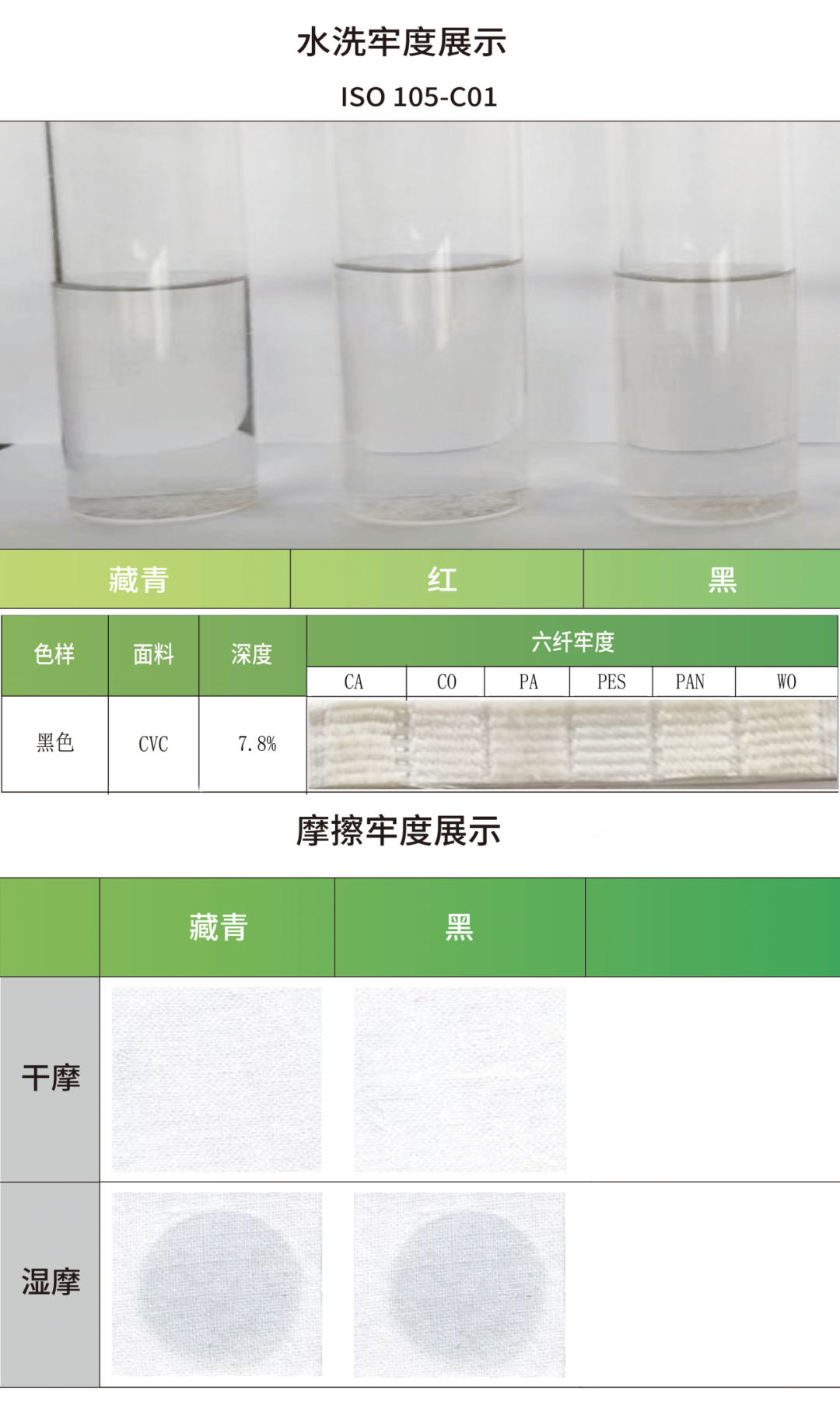

2. Stable Dyeing & High Reproducibility: Highly adjustable for different blends, easy color matching, strong process stability, high color sample approval rate, and excellent reproducibility, minimizing corrections and re-dyeing.

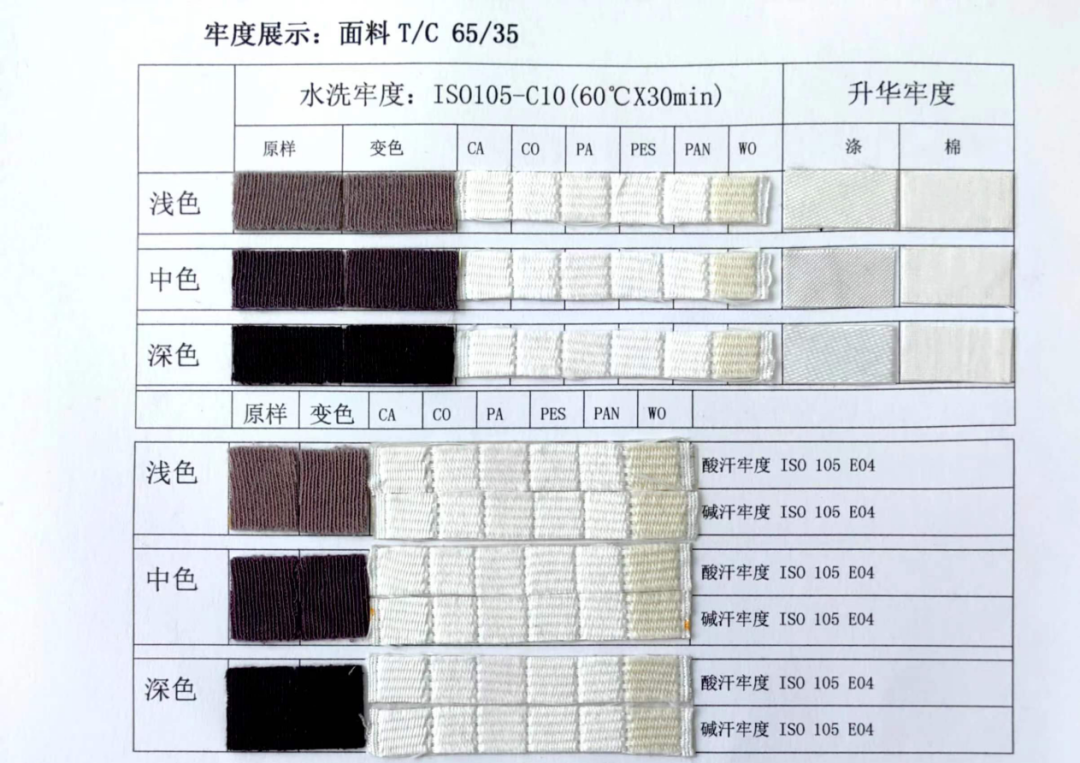

3. Excellent Fastness: Achieves washing fastness at Grade 4; rubbing fastness is improved by half a grade compared to conventional processes.

4. Energy Saving & Eco-Friendly: Eliminates the reduction clearing step in traditional processes, effectively reducing COD emissions and lowering water, electricity, and steam consumption, thereby aligning with clean production and energy-saving goals.

Application Prospects

Against the backdrop of green and low-carbon development, the polyester-cotton one-bath dyeing process, with its comprehensive advantages in efficiency, energy conservation, environmental protection, and quality stability, is spearheading the textile industry’s green transformation and upgrade. With continuous optimization and broader applications, it is gradually replacing traditional dyeing methods and showing great potential for expansion into various blended fabric fields. It is expected to become a core technology driving sustainable transformation in the textile industry, delivering both environmental benefits and stronger market competitiveness for enterprises.